Types:News

Click:2529

Time:2017-02-22 11:13:00

There is no need for rumors about the importance of water for human production and life. In today's rapid economic development, how to make water resources fully recycled and benefit future generations has become a worldwide proposition. Recently, a high-tech enterprise in Jiangbei District of Ningbo has achieved a major breakthrough in the field of water treatment relying on independent innovation. It has been awarded the “Top 100 New Technology and New Product” award by the Ministry of Science and Technology and has been called “Super Black Technology” by domestic counterparts. What exactly is the product produced by this company called Net Source Technology?

Turn the missile seal into a "water purification expert"

We are exposed to water every day, but most people don't know much about the question of how water is treated for production and life. Conventional water treatment methods include distillation, mechanical separation using physical principles such as sedimentation and air flotation, ion exchange, sand filtration, etc., but these methods generally have disadvantages such as high cost, low efficiency, and incomplete filtration.

In the 1990s, a method called membrane treatment - the use of plastic materials to filter membranes, purification of sewage into the market, and rapid development called the mainstream, the total output value of the industry rose from 200 million in 1993 to 2015 100 billion yuan. The material of the original filter membrane was mainly made of PVC. Later, Japan and the United States developed PVDF filter membranes to further enhance the performance.

The reason why Jingyuan Technology's film is called black technology is because the film is made of a new material, PTFE. The Chinese name of PTFE is called PTFE, which is made by the father of fluororesin Roy Planck. Founded in the late 1930s, it is known as the “Plastic King” and has excellent chemical stability and corrosion resistance. It is one of the best materials for corrosion resistance in the world today. Because it can withstand a height of 260 ° C, it has been used by the US military as a raw material for missile seals and has been kept secret until the end of the last century.

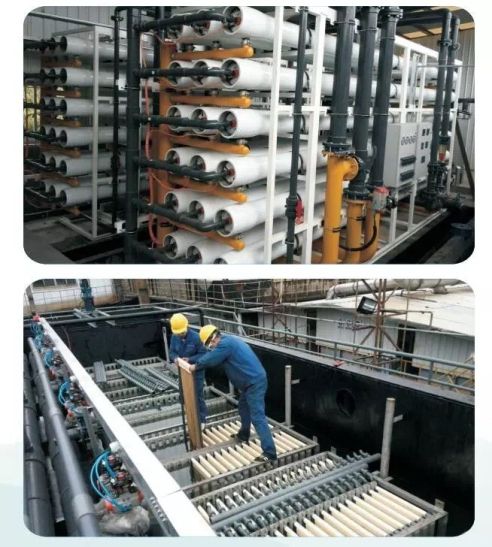

In the net source technology, general manager, one of the main developers of PTFE hollow fiber membranes, Wu Xiaochao showed this product to reporters. In appearance, the film is made into a long strip like a noodle, and the middle is hollow. There are numerous small holes on the surface with a diameter of less than 0.01 micrometer, which is equivalent to one-sixth of the diameter of the hair. Through the internal and external pressure difference, the sewage will be squeezed into the hollow space of the membrane through these small holes, and the harmful substances such as rust, sediment, colloid, bacteria, virus, macromolecular organic substances in the water will remain on the membrane while retaining beneficial to the human body. Some mineral elements.

"This filtration technology has a proprietary grade called ultrafiltration. If the water source is up to standard, then the water filtered through the membrane is the mineral water we usually drink." Wu said. This kind of process is widely used in large natural water plants, replacing traditional sand filtration technology to make tap water more clear and safe. At the same time, it can improve the form and water quality of rural drinking water, and it is impossible for the urban water supply network to extend to the mountains, islands, etc. Application in regional water supply.

Breaking foreign monopoly and filling domestic gaps

Compared with the previous PVC and PVDF membranes, the PTFE membrane has superior toughness. A noodle-thick film can withstand the weight of an adult and can work under strong acid and alkali and extreme temperature.

"For example, the electroplating factory and the printing and dyeing factory discharge waste water with a pH greater than 10 or less. The traditional PVC or PVDF membrane will dissolve, oxidize, produce water and purify after working in this environment for 3 months to half a year. The rate is greatly reduced and has to be replaced. The life of PTFE membrane can reach more than three years." Wu low tide said.

More importantly, the filtration membrane technology has been monopolized by Fortune 500 companies such as Dow Chemical, GE, Sumitomo, Mitsubishi, etc. Chinese buyers have no bargaining power, and foreigners say what price is.

"The market is dominated by foreigners. Without a creative technological breakthrough, it is impossible to survive in this industry. After all, GE and Mitsubishi have the capital and brand advantages that our small enterprises cannot match. So we are eyeing PTFE. Super plastic," he said.

In 2013, Sumitomo successfully developed a PTFE filter membrane and applied for patents in various intellectual property offices around the world to implement a technical blockade. Through three years of hard work, Wu Xiaochao's team independently developed the entire production equipment, successfully manufactured the PTFE hollow fiber membrane belonging to the Chinese, and obtained 19 national patents, becoming the second in the world. The only one in China can produce such products. Business. The price and performance of the foreign competitors are chilling, only a quarter of Japanese companies, close to the price of PVDF membranes of American companies.

Wu Xiaochao introduced that he had been working in the water treatment membrane laboratory of Dow Chemical in the United States before he founded the net source. He admitted that the price of foreign companies is four times its cost. If PTFE hollow fiber membranes are independently developed and produced, the cost of Chinese enterprises will be greatly reduced, and PTFE hollow fiber membranes fill the gap in this field and can be used in high-pollution and difficult-to-handle industrial wastewater treatment. biggest advantage.

This breakthrough also aroused the high attention of the "membrane industry leader", the academician of the American Academy of Engineering, and the foreign academician of the Chinese Academy of Sciences, Mr. Li Nianzhi. He made a special trip to the factory to inspect and put forward suggestions for improvement, which enhanced the competitiveness of the products.

(Fourth left Li Nianzhi)

Once the products of Jingyuan were quickly recognized by the market, the company cooperated with Zhejiang Fuchun Ziguang Environmental Protection Co., Ltd. to undertake the 25,000 tons of steel wastewater reuse project of Ningbo Iron and Steel Group's Ningbo Iron and Steel Plant every day, surpassing the project of Sumitomo in Japan. . In addition, the 35,000-ton electroplating wastewater treatment project of Jieyang Zhongde Metal Eco-city Surface Treatment Ecological Industrial Park Co., Ltd. is also undertaken by the net source. At the same time, it provided integrated water supply equipment for Maobei and Yuyao Dagu in Jiangbei District, so that mountain residents drank clean water and assured water.

Targeting the environment and locking the future

According to the data of the Municipal Environmental Protection Bureau, the current water resources in Ningbo are very tight, and the intensity of water resources development has exceeded the internationally recognized red line. A quarter of the city's water consumption relies on overseas water diversion, and the proportion of ecological water occupation total water has been Dropped to around 10%. Last year, the city's industrial sewage treatment capacity reached 400 million tons, emitting 160 million tons.

Scan It