The main processing methods of a refinery in Ningbo are direct distillation of crude oil, cracking and distillation of heavy oil and refining of some components. The production wastewater is mainly cooling water, oily wastewater, sulfur-containing wastewater, alkali-containing wastewater, and sometimes Acid-containing wastewater will also be discharged. The main pollutants in the wastewater are oil slick, emulsified oil, volatile phenol, CODcr, BOD5 and sulfide. In short, it is mainly based on organic matter and has good biochemical properties. In order to implement the national environmental protection policy and the requirements of the local environmental protection department, an environmental protection plan was formulated, and a new 600-ton/day sewage treatment project was established. 50% of the effluent was reused for the hydration of the circulating cooling water in the plant and the plant greening in the plant. Entrusted by it, our company (Ningbo Jingyuan Membrane Technology Co., Ltd.) conducted on-site inspection and water quality analysis of its plant, combined with our company's experience in wastewater treatment, designed the project.

The refinery 600 tons / day wastewater treatment project, the design of integrated wastewater influent water quality is as follows:

|

Name |

Unit |

Index value |

|

CODcr |

mg/l |

≤2000 |

|

pH |

- |

6~9 |

|

SS |

mg/l |

≤280 |

|

S2- |

mg/l |

20 |

|

NH3-N |

mg/l |

≤40 |

|

oil |

mg/l |

≤120 |

|

Name |

Unit |

Index value |

|

CODcr |

mg/l |

≤60 |

|

pH |

- |

7~8 |

|

SS |

mg/l |

≤10 |

|

S2- |

mg/l |

≤0.1 |

|

NH3-N |

mg/l |

≤10 |

|

oil |

mg/l |

≤5 |

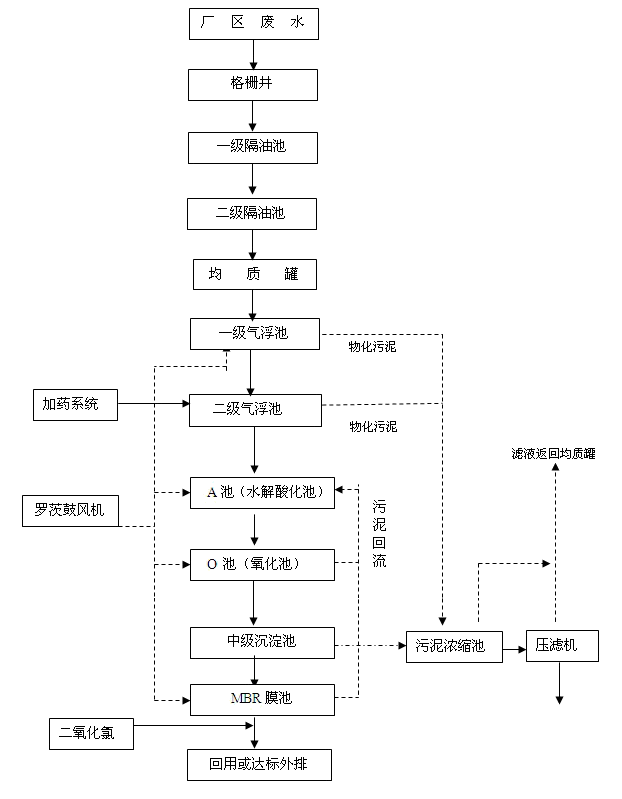

Project process:

Introduction to the project process:

The wastewater from the plant will flow into the grid well to remove large suspended solids or floating materials, such as fibers, plastic bags, and swarf wood chips, so as to reduce the processing load of the subsequent structures. Because of the high oil content of such wastewater, the wastewater first enters the two-stage grease trap to remove some oil and oil particles in the water. A steam heating line is arranged in the grease trap to warm the pool water during the cold season, improving the fluidity and treatment effect of the oil. After two stages of oil separation, the wastewater flows into the homogenization tank, and an aeration perforated tube is arranged in the homogenization tank to ensure uniform adjustment of water quality and water quantity. In order to ensure the removal of oil and other toxic and hazardous substances, the water in the tank is uniformly fed into the two-stage dissolved air flotation equipment by the sewage pump, and the oil slick is effectively removed by adding the coagulant and the coagulant. , emulsified oil, toxic and hazardous substances, etc. Ensure the normal operation of the subsequent biochemical treatment and membrane separation system. After the air flotation treatment, the sewage flows into the hydrolysis acidification tank. The main function of the hydrolysis acidification tank is to degrade the macromolecular organic matter in the wastewater into small molecular substances, and the difficult biodegradable substances are converted into biodegradable substances. Meanwhile, the hydrolysis acidification tank has Better resistance to organic load and toxicity; degradation of solid organic matter can reduce sludge volume. The water in the hydrolysis acidification tank flows into the aerobic pool, and is metabolized by aerobic bacteria in the aerobic tank for aerobic treatment, and the pollutants in the water are oxidized and decomposed into CO2 and H2O to complete the removal of organic matter. The treated water flows into the intermediate sedimentation tank for sludge water separation. The water separated by the mud in the intermediate sedimentation tank enters the MBR membrane tank, and the wastewater is filtered by a CFP series immersion (curtain) membrane separation module independently developed by our company (Net Source Membrane Technology Co., Ltd.). Because of its effective retention, microorganisms with a long generation period can be retained, and the sewage can be deeply purified. At the same time, the nitrifying bacteria can fully reproduce in the system, and the nitrification effect is obvious, which provides a basis for deep phosphorus removal and nitrogen removal. The MBR membrane effluent is sterilized by the chlorine dioxide generator and then enters the reuse tank.

The sludge of the materialized sludge and biochemical system in the air floatation tank is discharged into the sludge concentration tank, dehydrated by a filter press, and transported to a landfill for treatment.

Scan It