Project Project Photo: Pressurized dissolved air flotation cell in the system

Ningbo Xiangshan Paper Co., Ltd. has four paper machines, one for 1760 paper machines, one for 1575 paper machines, and two for 1092 paper machines. Three of them are actually used, and one of them is not put into use. Its main products are corrugated paper, cardboard paper electromechanical sound paper, one 1092 paper machine to produce electroacoustic paper, the raw materials used are rubber packaging waste paper, and the other two paper machines produce corrugated and cardboard paper, corrugated paper production accounts for about 2/3 The production of cardboard paper accounts for about 1/3. There are two main types of wastewater in the plant: one is corrugated paper, boardboard paper production wastewater, the water volume is about 3,000 tons / day; the second is electroacoustic paper production wastewater, the water volume is about 1,500 tons / day. The original treatment station of 2,000 tons/day in the plant area is now implementing the environmental protection plan and implementing the new 2,500 tons/day sewage treatment project for the implementation of the national environmental protection policy and the requirements of the local environmental protection department. Entrusted by it, our company (Ningbo Jingyuan Membrane Technology Co., Ltd.) conducted on-site inspection and water quality analysis of its plant, combined with our company's experience in papermaking wastewater treatment, designed and constructed the project.

The company's 3,000 tons / day wastewater treatment project, the design of integrated wastewater influent water quality is as follows:

| Name | Unit | Index value |

| CODcr | mg/l | ≤500 |

| BOD5 | mg/l | ≤200 |

| pH | - | 7~8 |

| SS | mg/l | ≤400 |

|

Chromaticity (dilution factor) |

- | ≤500 |

|

Name |

Unit |

Index value |

|

CODcr |

mg/l |

≤80 |

|

BOD5 |

mg/l |

≤20 |

|

pH |

- |

6~9 |

|

SS |

mg/l |

≤30 |

|

Chromaticity (dilution factor) |

- |

≤50 |

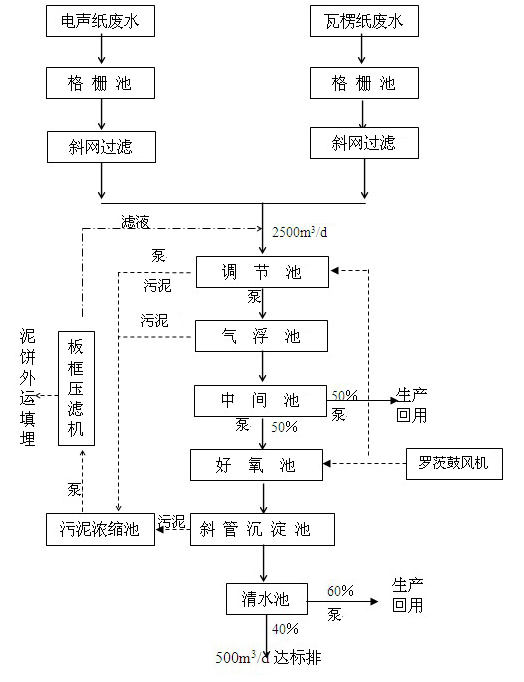

Project process:

Introduction to the project process:

The two production wastewaters in the plant area are respectively removed from the respective grid cells by large suspended solids or floating objects, such as fibers and broken wood chips, so as to reduce the processing load of the subsequent structures, and then filtered through a diagonal net to remove suspended solids, pulp and large The particulate impurities are then self-flowed into the conditioning cell. A perforated aeration pipe is arranged in the adjustment tank for auxiliary agitation and pre-aeration. The sewage is adjusted in the pool to adjust the water volume and homogenize the water quality, and the quenched and tempered water is pumped to the air flotation system for treatment. In the air floating pool, the flocculant and the coagulant are added before the pump to remove the colloidal suspended matter and organic matter in the wastewater; the effluent flows into the intermediate pool. 50% of the primary treatment water in the intermediate tank is pumped to the plant for beating and reuse, and the rest is pumped to the biochemical pool for biochemical treatment. In the biochemical pool, the aerobic bacteria permeating on the filler is metabolized at high speed, and aerobic treatment is carried out to oxidize and decompose the pollutants in the water into CO2 and H2O, complete the removal of the organic matter, and remove the biochemical effluent and then flow into the inclined tube sedimentation tank for sedimentation treatment. After direct discharge to the standard. The sludge discharged from the air floating pool, the biochemical pool and the inclined tube sedimentation tank is collected into a sludge concentration tank and subjected to centralized dehydration treatment by a plate and frame filter press. The dewatered sludge and the solid waste in the plant area are transported to the landfill for landfill through special solid waste transportation vehicles.

Scan It