Project Description: Shanxi Aluminium Industry Co., Ltd. main products are alumina, chemical alumina, recycled aluminum alloy, cement, caustic soda, aluminum profiles. The wastewater generated by the enterprise in the production process mainly comes from the on-site alkali-containing waste liquid, the production equipment cooling water, the sewage chemical regeneration wastewater, the production wastewater of the plant-owned thermal power plant and the production and drainage of other subsidiary units. The total wastewater is about 8,000. Tons / day. Entrusted by the company, our company (Ningbo Jingyuan Membrane Technology Co., Ltd.) undertakes the design work of the design scheme of the production wastewater treatment station. Through multiple site surveys, investigations and data collection, and repeated major research on the main economic and technical issues in the project, and related local departments and engineering and technical personnel, after a comprehensive technical and economic analysis and comparison, the project design was completed.

Main indicators of influent water quality: alkali (O.17-0.32 mg/L for Na20), oil (≤120mg/L), and suspended solids (60-220mg/L). After the wastewater treatment system, the water quality meets the “Aluminum Industry Pollutant Discharge Standard” (GB25465-2010). The water quality is as follows in Table 1. At the same time, the wastewater treated with the wastewater is used as the raw water for the hydration of the circulating water field in the plant. To meet the requirements of the aluminum industry, the water quality indicators should reach Table 2.

| Name | Unit | Index value |

| CODcr | mg/l | ≤60 |

| pH | - | 6~9 |

| SS | mg/l | ≤30 |

| Volatile phenol | mg/l | ≤0.5 |

| NH3-N | mg/l | ≤8.0 |

| Total phosphorus | mg/l | ≤1.0 |

| Oil | mg/l | ≤3 |

Table 2

| Name | Unit | Index value |

| pH | - | 7~8 |

| Turbidity | NTU | ≤5 |

| iron | mg/l | ≤0.1 |

| Al | mg/l | ≤1 |

| Silica | μg/L | ≤120 |

| hardness | umol/l | ≤2 |

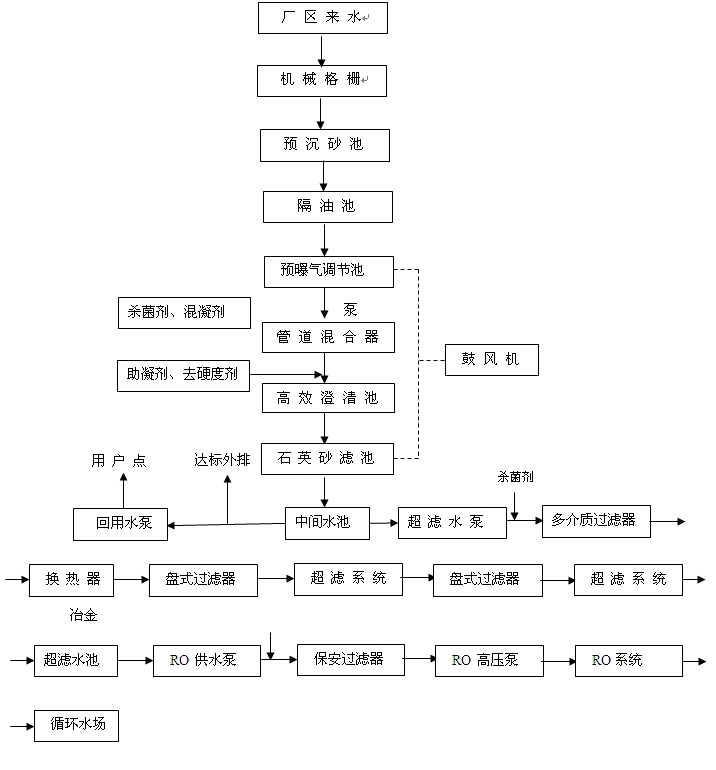

Shanxi Aluminium Industry Co., Ltd.'s wastewater treatment system mainly includes two treatment systems, namely, a water reuse treatment system and a circulating water treatment system. The water reuse treatment system is divided into mechanical grid, pre-sanding sand, grease trap, pre-aeration, clarification tank, quartz sand filter and dosing unit. The circulating water treatment system is divided into a multi-media filter, an ultrafiltration, a reverse osmosis and a dosing and cleaning unit. In the water reuse system, the water coming from the plant first removes large solids, floating objects, etc. through the mechanical grille, and then enters the pre-sanding sand to remove large-grained sand through the grid to ensure the normal operation of the later processing system. After the grit wastewater enters the grease trap, some oil and oil particles in the water are removed. A steam heating line is arranged in the grease trap to warm the pool water during the cold season, improving the fluidity and treatment effect of the oil. After the effluent enters the pre-aeration regulating tank and the water quality and quantity, the raw water pump is lifted into the high-density clarifier, and the lime, coagulant and coagulant dosing device are set in the water inlet of the high-density clarifier, and the mixed flocculation and sedimentation is reduced. The suspended solids of the raw water, hardness, etc., the deep effluent of the effluent through the gas-water backwashing filter further removes suspended matter and other impurities, and then is stored in the intermediate pool. Part of the effluent from the intermediate pool is supplied to the designated user (for rinsing of the floor of the workshop) through the reuse pump or directly to the outside of the standard. The other part is sterilized by the sterilizing agent and then lifted to the circulating water treatment system through the ultrafiltration water supply pump.

The circulating water treatment system is used to raise the water in the intermediate pool by the ultrafiltration water supply pump, and then pre-treat through the multi-media filter, heat exchanger, self-cleaning filter and ultrafiltration device to further remove iron, manganese, suspended matter, colloid and organic matter. Residual contaminants, while removing bacteria and algae by adding fungicides. In the UF ultrafiltration system, the ultrafiltration membrane adopts the wastewater reuse type SFW-D2 membrane module independently developed by our company (Ningbo Jingyuan Membrane Technology Co., Ltd.), and its filtered water production SDI≤1, water production turbidity ≤0.1NTU . It has a long service life and easy to clean. The ultrafiltration effluent is stored in the ultrafiltration production tank, and is lifted to the security filter by the reverse osmosis water supply pump, and the scale inhibitor and reducing agent are added to reduce the scale and oxidant pollutants in the water to ensure the normal operation of the system, and then the high pressure. The pump is boosted and sent to the reverse osmosis unit for desalination treatment, and the effluent enters the circulating water field. In the RO reverse osmosis system, the reverse osmosis membrane is a Dow BW30FR-400 membrane module with high antimicrobial and easy-to-clean properties. The concentrated water produced by the RO is returned to the pre-aeration conditioning tank for further processing.

The bulk waste of the grid well, the sand of the grit chamber, and the sludge of the clarifier are disposed together with the garbage produced and produced in the plant area as solid waste to the landfill.

Scan It