Project Description: The main site of Ningbo Iron and Steel Co., Ltd. is located in Beilun District, Ningbo City, Zhejiang Province, covering an area of 2.33 square kilometers and 38 kilometers from the urban area. The company's main production equipment is two 55-hole coke ovens, two 2500 cubic meters blast furnaces, three 180-ton converters, an annual production capacity of 1.8 million tons of double-station RH vacuum refining furnace, a 1780mm hot rolling production line, the first phase of design The annual production capacity is 4 million tons. The main equipment of the project has reached the domestic advanced level and is in line with international standards.

Ningbo Iron and Steel Co., Ltd. is a large-scale modern Linhai Iron and Steel Joint Enterprise with complete equipment and first-class equipment from raw materials to iron making, steel making, continuous casting and hot rolling. It has a superior geographical location with developed transportation and smooth logistics. The west side is adjacent to Beilun Port, a famous deep-water port in the world, and the Beilun Port iron ore transfer yard on the west side of the station.

At present, the centralized treatment of circulating water and sewage in the central water station of Ningbo Iron and Steel Co., Ltd. is discharged into the sea directly, which wastes water resources and does not meet the “zero emission” requirements of Ninggang Company's wastewater. Therefore, the project will deeply treat and reuse the drainage of the central water station of Ningbo Iron and Steel Co., Ltd.

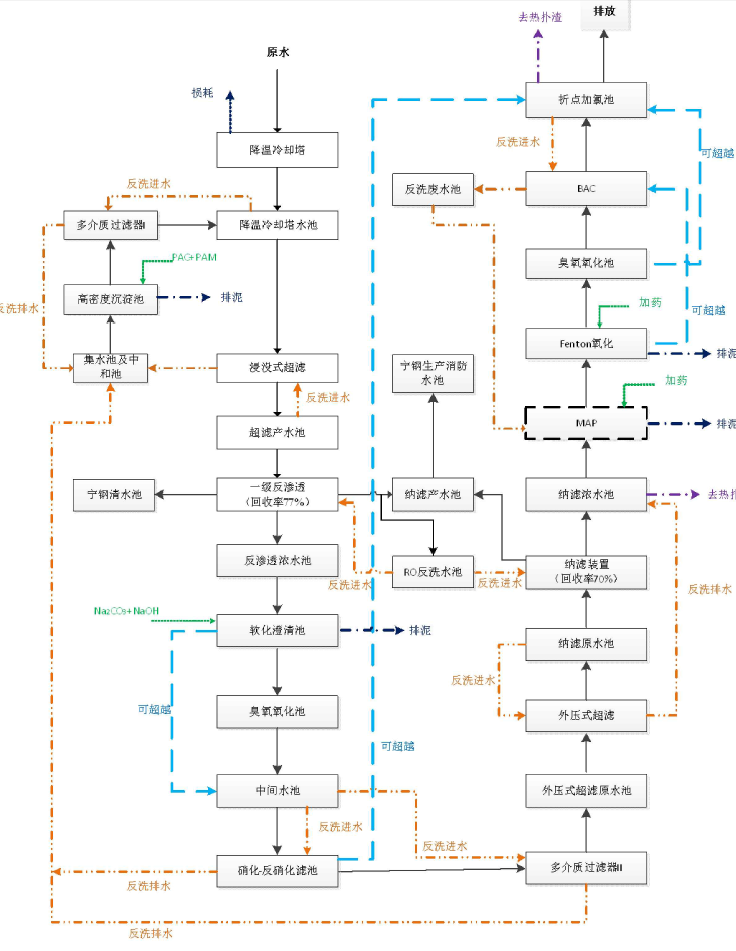

The system is the BOT project for deep treatment of sewage from Ningbo Iron and Steel Co., Ltd., and the fire water supply for the whole station of Ningsteel is prepared from a certain proportion of the water from the reclaimed water, production water and large industrial water, but the salt content and calcium are produced due to the production of recycled water. Hardness and chloride ion are high, and the water temperature in summer is high, which can not completely reuse the water from the central sewage treatment station. A large amount of water is directly discharged into the sea every day. In order to save resources and reduce pollutants, it is decided to build Ningbo Steel sewage depth. Processing station. The total construction scale of the first phase of the project is 25,000 m3/day (cooling tower design capacity is 36,000 m3/day). According to the raw water quality, treated water volume and water requirements, the system is operated under the premise of meeting the water quality standards. Reliable, economical investment in engineering, low operating costs, etc., using "cooling cooling + immersion ultrafiltration treatment (water production scale 25000m3 / h) + reverse osmosis treatment (recovery rate 77%) + concentrated water treatment (advanced Oxidation + softening clarification + micro-media filter) + concentrated water nanofiltration desalting treatment + super concentrated water advanced oxidation treatment process.

The 25,000m3/d wastewater treatment project of the steel plant, the design of integrated wastewater influent water quality is as follows:

|

Name |

Unit |

Index value |

|

temperature |

℃ |

20~35 |

|

pH |

|

7.0~8.5 |

|

SS |

mg/l |

≤5 |

|

Turbidity |

NTU |

≤5 |

|

oil |

mg/l |

<2 |

|

total hardness |

mg/l (以CaCO3计) |

230~550 |

|

Dissolved solid |

mg/l |

634~1066 |

|

Total iron |

mg/l |

0.06~1.2 |

|

C1- |

mg/l |

273~500 |

|

CODcr |

mg/l |

<30 |

|

Ammonia nitrogen |

mg/l |

<10 |

|

Residual chlorine |

|

0.2~0.4 |

|

Total number of bacteria |

|

≤3×104 |

|

Conductivity |

μS/cm |

1400~2300 |

|

Total nitrogen |

mg/l |

<10 |

|

Total phosphorus |

mg/l |

<1 |

Project process:

Project Engineering Picture: Membrane Pool in the System

Project Engineering Picture: Submerged Ultrafiltration Workshop in the System

Project Project Picture: Submerged reverse osmosis and sodium filtration workshop in the system

Scan It