Project Profile: Hebei Iron and Steel Co., Ltd. is a subsidiary company of Hebei Iron and Steel Group. Its main hot-rolled medium-width steel, billet, rectangular billet, slab, tube billet, etc., according to the company's strategic development plan and national environmental policy and The requirements of local environmental protection departments actively promote national energy conservation and emission reduction. The company's requirements are not only to achieve wastewater discharge standards, but also to save water resources, reduce sewage emissions, and achieve the dual purpose of reducing pollution and reduce emissions; require water source to reduce or eliminate pollutants into the water, using effective circulating water Treatment system, terminal total discharge wastewater treatment and reuse. According to the requirements of enterprise and national environmental protection for wastewater treatment of iron and steel enterprises, our company proposes the following design.

The design raw water adopts tailings reservoir water, tailings reservoir water sample, and the water quality is the inspection report of Beijing Physical and Chemical Analysis and Testing Center, see Table 1:

| Test items | Test result | Test items | Test result |

| aluminum | 0.11mg/L | Total alkalinity | 178mg/L |

| boron | 1.77mg/L | Volatile phenol | <0.002mg/L |

| barium | 0.19mg/L | Suspended matter | 8mg/L |

| calcium | 137mg/L | Sulfide | <0.005mg/L |

| copper | 0.19mg/L | Carbonate (CO32-) | 16.6mg/L |

|

iron |

0.20mg/L | Bicarbonate (HCO3-) | 182mg/L |

| Potassium | 36.8mg/L | Silica | 14.3mg/L |

| magnesium | 38.0mg/L | Nitrite nitrogen | 0.351mg/L |

| manganese | 0.096mg/L | Soluble total phosphate | 0.076mg/L |

| sodium | 146mg/L | Solubility total solid | 1.05*103mg/L |

| strontium | 0.75mg/L | Chemical oxygen demand CODcr | <10mg/L |

| Zinc | <0.001mg/L | Oxygen consumption (CODMn) | 1.54mg/L |

| lead | <0.0005mg/L | 5-day biochemical oxygen demand BOD5 | <0.5mg/L |

| PH value | 8.47 | Fluoride | 4.86mg/L |

| Conductivity | 1.196mS/cm | nitride | 271mg/L |

| Chroma | <5 degrees | Nitrate (in N) | 5.76mg/L |

| Stinky | Odorless and taste | Sulfate | 307mg/L |

| Turbidity | 2NTU | Petro | <0.1mg/L |

| Ferrous | <0.03mg/L | Total organic carbon | 3.47mg/L |

| Ammonia nitrogen | 0.51mg/L | Total number of colonies | 3.0*104CFU/mL |

| total hardness | 487mg/L | Total coliform |

79MPN/100mL |

The water quality of the designed water discharge should meet the water reuse standard of the circulating water produced by the enterprise. The specific indicators are shown in Table 1. At the same time, the soft water quality indicators should meet the following indicators as shown in Table 2.

| Serial number | Project | Unit | Control indicator |

| 1 | PH | 6.5~8.0 | |

| 2 | suspended matter | mg/L | ≤5 |

| 3 | turbidity | NTU | ≤5 |

| 4 | CODcr | mg/L | ≤10 |

| 5 | petroleum | mg/L | ≤2 |

| 6 | BOD5 | mg/L | ≤0.5 |

| 7 | Total hardness (calculated as CaCO3) | mg/L | ≤300 |

| 8 | Calcium hard (calculated as CaCO3) | mg/L | ≤200 |

| 9 | alkalinity | mg/L | ≤250 |

| 10 | total dissolved solids | mg/L | ≤1000 |

| 11 | ammonia nitrogen | mg/L | ≤5 |

| 12 | total iron | mg/L | ≤0.5 |

| 13 | free residual chlorine | mg/L | end 0.1 ~ 0.2 |

| 14 | Total bacteria | /mL | <1000 |

| Note: When the total dissolved solids content of the effluent is >1000mg/L, deep desalination should be carried out. | |||

| Serial number | Project | Unit | Numerical value |

| 1 | hardness | μmol/l | ≤2.0 |

| 2 | Silica | μg/L | ≤100 |

| 3 | Conductivity (25 ° C) | μs/cm | ≤50 |

| 4 | Total Fe | μg/L | <50 |

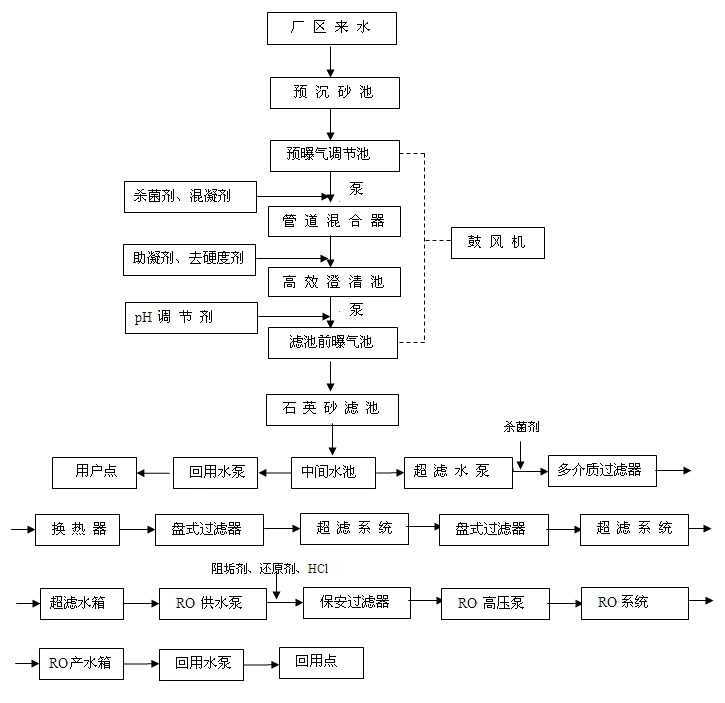

Project process

The sewage treatment system of a steel company in Hebei mainly includes two treatment systems: a water reuse treatment system and a soft water treatment system. The water reuse treatment system is divided into pre-sanding, pre-aeration, clarification tank, filter tank and dosing unit. The soft water system is divided into a multi-media filter, ultrafiltration, reverse osmosis and dosing, cleaning unit. In the water reuse system, the water from the plant area is pre-sanded to remove large particles of sand to ensure the normal operation of the later processing system. After the effluent enters the pre-aeration regulating tank and the water quality and quantity, the raw water pump is lifted into the high-density clarifier, and the lime, coagulant and coagulant dosing device are set in the water inlet of the high-density clarifier, and the mixed flocculation and sedimentation is reduced. The suspended solids of the raw water, the hardness, etc., and the effluent are further subjected to deep filtration by the steam-water backwashing filter to further remove suspended matter and other impurities, and then stored in the intermediate pool. Part of the effluent from the intermediate pool is supplied to the designated user (such as selected, sintered, pellets, etc.) by the reuse pump, and the other part is sterilized by the sterilizing agent and then lifted to the soft water system through the ultrafiltration water supply pump. The sludge from the clarification tank enters the sludge storage tank and is disposed of by landfill after dewatering to avoid secondary pollution.

In the soft water system, the water storage in the middle pool is upgraded by the ultrafiltration water supply pump through the multi-media filter, heat exchanger, self-cleaning filter and ultrafiltration device to further remove iron, manganese, suspended matter, colloid and organic matter residue pollution. And remove bacteria and algae by adding fungicides. The effluent is stored in the ultrafiltration production tank, and is lifted to the security filter by the reverse osmosis water supply pump, and the scale inhibitor and reducing agent are added to reduce the scale and oxidant pollutants in the water to ensure the normal operation of the system, and then pumped up by the high pressure pump. The pressure is sent to the reverse osmosis unit for desalination treatment, and the effluent is stored in the reverse osmosis production tank. The high pressure soft water pump and the low pressure soft water pump are supplied to the steelmaking and iron making users. The reverse osmosis concentrated water is stored in the concentrating pool and supplied to the new district by the concentrated water pump. Slag pool, iron slag slag pool and material yard spray water.

The bulk waste of the grid well, the sand of the grit chamber, the sludge of the clarifier, etc. are transported together with the solid waste of the plant area as solid waste to the landfill.

Project project picture: reuse pool and reverse osmosis equipment in the system

Scan It