Project Description: Ningbo Shock Absorber Co., Ltd. has professional production testing equipment and modern rooms, as well as professional technicians to conduct product research and development, quality testing, technology and manufacturing capabilities. It is dedicated to the development of shock absorbers for auto parts, and can produce shock absorbers for various models. Currently, there are more than 1,100 shock absorbers developed and produced, mainly exported to North America, South America, Europe, Middle East and Africa. The sewage generated in the production process is mainly acid washing, phosphating wastewater, dewatering, derusting and surface oxidation treatment wastewater, as well as pipelines, equipment and ground washing wastewater. The key pollutants of the wastewater are CODcr, PO43-, petroleum and Zn2+, etc., the total amount of wastewater is about 120 tons / day. In order to implement the national environmental protection policy and the requirements of the local environmental protection department, an environmental protection plan was formulated, and a new 120-ton/day sewage treatment project was established. Entrusted by it, our company (Ningbo Jingyuan Membrane Technology Co., Ltd.) conducted on-site inspection and water quality analysis of the sewage treatment project, combined with our company's experience in hardware wastewater treatment, designed and constructed the project.

The company's comprehensive wastewater quality is as follows:

| Name | Unit | Index value |

| CODcr | mg/l | 150-200 |

| pH | - | 4.5-6.0 |

| 色度 | ≤90 | |

| PO43- | mg/l | ≤30 |

| 油 | mg/l | ≤20 |

| Zn2+ | mg/l | ≤100 |

The effluent quality of the company is better than the first-level discharge standard of Integrated Wastewater Discharge Standard (GB8978-1996). The standard water quality indicators are as follows:

| Name | Unit | Index value |

| CODcr | mg/l | ≤100 |

| pH | - | 6.0-9.0 |

| Chroma | ≤50 | |

| PO43- | mg/l | ≤0.5 |

| oil | mg/l | ≤5 |

| Zn2+ | mg/l | ≤2 |

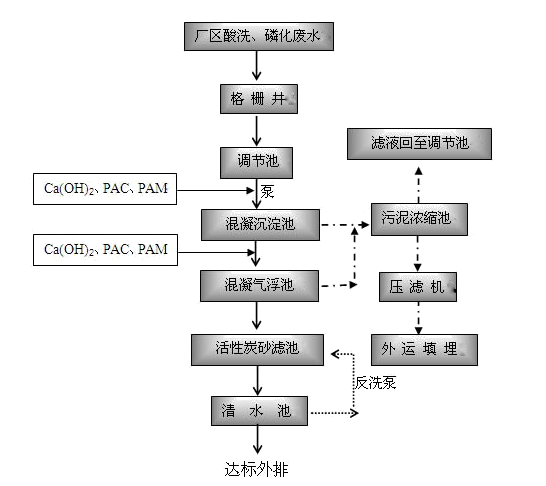

Project process:

Project process description:

The production wastewater from the workshop is sent to the wastewater treatment station through the waste water pipeline. Self-flow through the grille grille to remove large solid suspended solids, enter the regulating tank, and the wastewater is adjusted to the water and water volume through the regulating tank, then lifted into the coagulation reaction tank by the wastewater lifting pump, and Ca(OH)2 is added to the reaction tank to adjust The pH value is controlled to control the pH value of the water in the reaction cell between 10.0-11.0, and the flocculation reaction is carried out by adding PAC and PAM. After the flocculation reaction is completed, the coagulation inclined tube sedimentation tank is entered for solid-liquid separation, and the calcium phosphate and most of the calcium phosphate are completed. The precipitation of zinc hydroxide precipitates the sludge into the sludge concentration tank. The effluent from the sedimentation tank flows into the air-floating coagulation reaction tank. In the air-floating coagulation reaction tank, the above-mentioned agent is also added to the oil-water separation in the air-floating tank through the release device, thereby further removing CODcr, PO43-, petroleum and Zn2+. The separated scum is scraped into the sludge discharge pipe by the scraper and finally flows into the sludge concentration tank; the effluent from the air floatation tank passes through the quartz sand activated carbon filter, and the CODcr and PO43 in the water are further removed by the filtration of quartz sand and the adsorption of activated carbon. - Wait, the filter effluent enters the clear water tank, the water in the clear water tank is discharged through the standard discharge port, and the filter tank can be backwashed by the backwash pump after the filter tank is fouled. The sludge of the sludge concentration tank is dehydrated by the diaphragm pump and injected into the plate and frame filter press, and the filtrate is returned to the adjustment tank, and the dry mud treatment is regularly cleaned and transported for harmless disposal.

Project project picture: coagulation sedimentation tank and air flotation equipment in operation

Scan It