Project Description: A domestic waste incineration power generation project in Jiangsu Province will burn 500 tons of domestic garbage and 200,000 tons of garbage per year. The waste incineration plant uses waste heat to generate electricity, the waste heat boiler and the steam turbine generator set are configured as medium-temperature medium-pressure, 2 waste heat boilers, and the steam turbine generator set is a 12MW condensing steam turbine generator set. The project leader entrusted our company to design a chemical makeup water treatment system for its 10MW condensing steam turbine generator set.

The raw water designed for this system is the tap water of the plant.

After the system treatment, the water quality of the boiler feed water treatment system is reached:

Silica: ≤20ug/l;

Conductivity (25 ° C): ≤ 0.2 uS / cm;

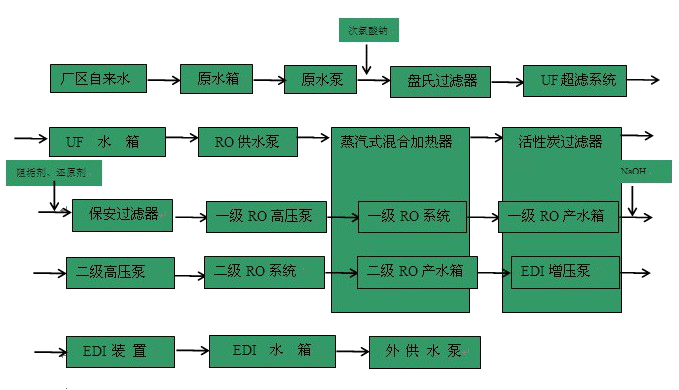

Project process:

Introduction to the project process:

The tap water in the plant will flow into the original water tank through the original water pressure. The water in the original water tank is boosted by the original water pump and added with sodium hypochlorite fungicide. Then it enters the self-cleaning disc filter to remove some coarse particles and impurities, and the water enters the UF super. In the filtration system, the ultrafiltration membrane adopts SPN-C2 membrane independently developed by our company (Ningbo Jingyuan Membrane Technology Co., Ltd.), and its filtration water production SDI≤1, water production turbidity≤0.1NTU. The ultrafiltration system effluent enters the ultrafiltration water tank, and the ultrafiltration water tank enters the steam mixing heater through the reverse osmosis water supply pump. Its main function is to ensure that the subsequent RO system and the EDI system can guarantee the normal operation function in the winter with lower temperature. The heater effluent enters the activated carbon filter, which mainly removes suspended matter and odor, residual chlorine, organic matter, etc., further ensuring the water quality, and also checks the service life of the subsequent RO system and the EDI system. Activated carbon effluent passes through a 5um-grade security filter and adds scale inhibitors and reducing agents to the water to reduce the scale and oxidizing substances of the reverse osmosis membrane. The effluent enters the first-stage RO system. The reverse osmosis membrane of the RO system is Dow. BW30FR-365 membrane module with high anti-microbial and easy-to-clean properties. The primary RO system effluent can remove more than 97% of dissolved solids in raw water, more than 99% of organic matter and colloids, almost all bacteria, the recovery rate of primary RO system is ≥75%, and the salt rejection rate is ≥98%. The effluent from the primary RO system enters the RO production tank. The water in the RO water tank is raised to the secondary RO system by a secondary high pressure pump. Since the reverse osmosis water is slightly acidic, the pH value is small after the first reverse osmosis. In order to meet the process requirements, the membrane element requires the inlet water to be neutral before the secondary RO system. This pair of secondary reverse osmosis membranes Long-term stable operation and great benefit to salt rejection and water production, the recovery rate control is ≥85%, and the salt rejection rate is ≥99.5%. The secondary RO system effluent makes the water conductivity below 10μs, and then enters the secondary RO tank. The water is transported to the EDI system through the EDI booster pump. The EDI system is 6 sets of GE MK-3 membrane blocks, which further removes the unremoved salts in the anti-seepage system. The recovery rate is ≥90%, ensuring the effluent. The water quality of the boiler feed water treatment system is reached. The EDI system effluent enters the water tank and is sent to the boiler water point through the variable frequency pump.

Project Engineering Photo: System Ultrafiltration Reverse Osmosis Equipment

Scan It