Project Description: According to the “Application Report of Sewage Treatment Plant Project of Certain City” and the “Reply on the Overall Arrangement of Long-term Sewage Scale of Certain City and the Implementation of Recent Scale”, the design scope of this project is sewage treatment in a certain city. The factory, specifically: the sewage plant is arranged in a one-time overall arrangement according to the long-term scale of 20,000 tons/day, and is constructed in two phases; it is designed and implemented according to the scale of 10,000 tons/day. Among them, the sewage pumping station and grit chamber at the front end of the sewage treatment process are designed according to the scale of rain and sewage combined flow, with a long-term of 40,000 tons/day and a recent capacity of 20,000 tons/day (closed multiple n=1).

200000 tons/day in a county Municipal water quality index of municipal sewage treatment project

| Name | Unit | Index value |

| CODcr | mg/l | ≤400 |

| BOD5 | mg/l | ≤200 |

| pH | - | 6~9 |

| SS | mg/l | ≤250 |

| NH3-N | mg/l | ≤25 |

After the wastewater is treated, it is superior to the Class A standard of the Pollutant Discharge Standard for Urban Sewage Treatment Plants (GB18918-2002). The specific indicators of the standard are as follows:

| Name | Unit | Index value |

| CODcr | mg/l | ≤50 |

| BOD5 | mg/l | ≤10 |

| pH | - | 6~9 |

| SS | mg/l | ≤10 |

| NH3-N | mg/l | ≤8 |

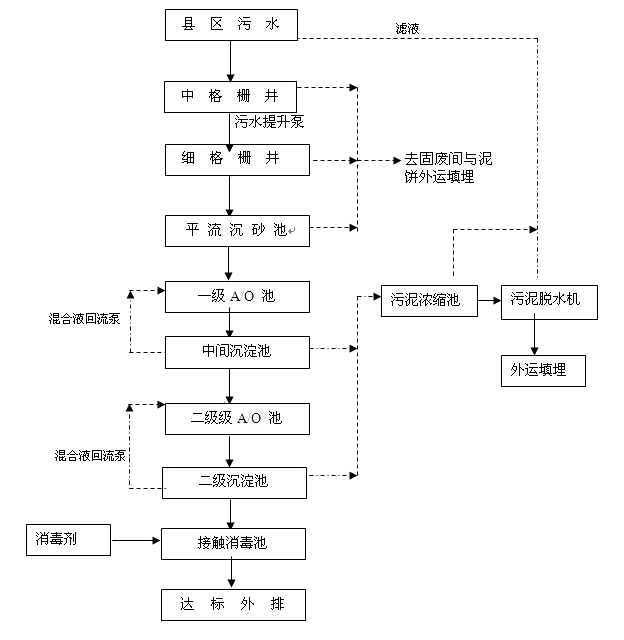

Project process:

Project process description:

The industrial, enterprise and residential wastewater in the county area is laid to the suburban sewage treatment station through the municipal drainage pipe network. The sewage first passes through the middle grille to remove large suspended matter or floating objects, such as fiber and broken wood chips, so as to reduce the subsequent structures. The treatment load, and then lift the water in the underground sewage well to a fine grid well of 5m through the sewage lifting pump to further remove some small debris fragments, and the fine grid well water flows through the advection grit chamber to remove the sand in the wastewater. Fine particles of finer particles and density than water to prevent damage to subsequent biochemical treatment equipment. The sewage from the advection grit chamber flows into the primary A/O denitrification and dephosphorization system. In this system, the aerobic section of the front section and the aerobic section of the latter section are connected in series. The DO of the A section is not more than 0.2 mg/L, the O section. DO = 2 to 4 mg/L. In the anoxic section, the heterotrophic bacteria hydrolyze the suspended pollutants and soluble organic matter such as starch, fiber and carbohydrate in the sewage into organic acids, so that the macromolecular organic matter is decomposed into small molecular organic substances, and the insoluble organic substances are converted into soluble organic substances. When the product of anoxic hydrolysis enters the aerobic tank for aerobic treatment, the biodegradability and oxygen efficiency of the sewage can be improved; in the anoxic section, the heterotrophic bacteria aminate the protein, fat and other contaminants (on the organic chain) The amino group in N or amino acid is free of ammonia (NH3, NH4+). Under sufficient oxygen supply conditions, the nitrification of autotrophic bacteria oxidizes NH3-N(NH4+) to NO3-, and returns to the A pool through reflux control. Under anoxic conditions, the denitrification of the aerobic bacteria reduces NO3- to molecular nitrogen (N2) to complete the cycle of C, N, and O in the ecology, and realize the harmless treatment of sewage. The O pool flows into the intermediate sedimentation tank to separate the mud and water. Part of the sewage in the sedimentation tank passes through the sludge concentration tank to remove the phosphorus from the sewage, and another part can be returned to the primary A/O system to enhance the denitrifying bacteria. The age of the mud increases the population of denitrifying bacteria to improve the efficiency of denitrification. The effluent from the intermediate sedimentation tank enters the secondary A/O system to further enhance the effect of nitrogen and phosphorus removal. The O pool of the secondary A/O system re-enters the secondary The sedimentation tank removes the sludge and SS particles flowing out of the water in the O pool, and separates the mud water. Finally, the wastewater separated by muddy water enters the contact disinfection tank for disinfection treatment and reaches the first-class A standard and then efflux.

Project project picture: auxiliary stream sedimentation tank in operation

Scan It